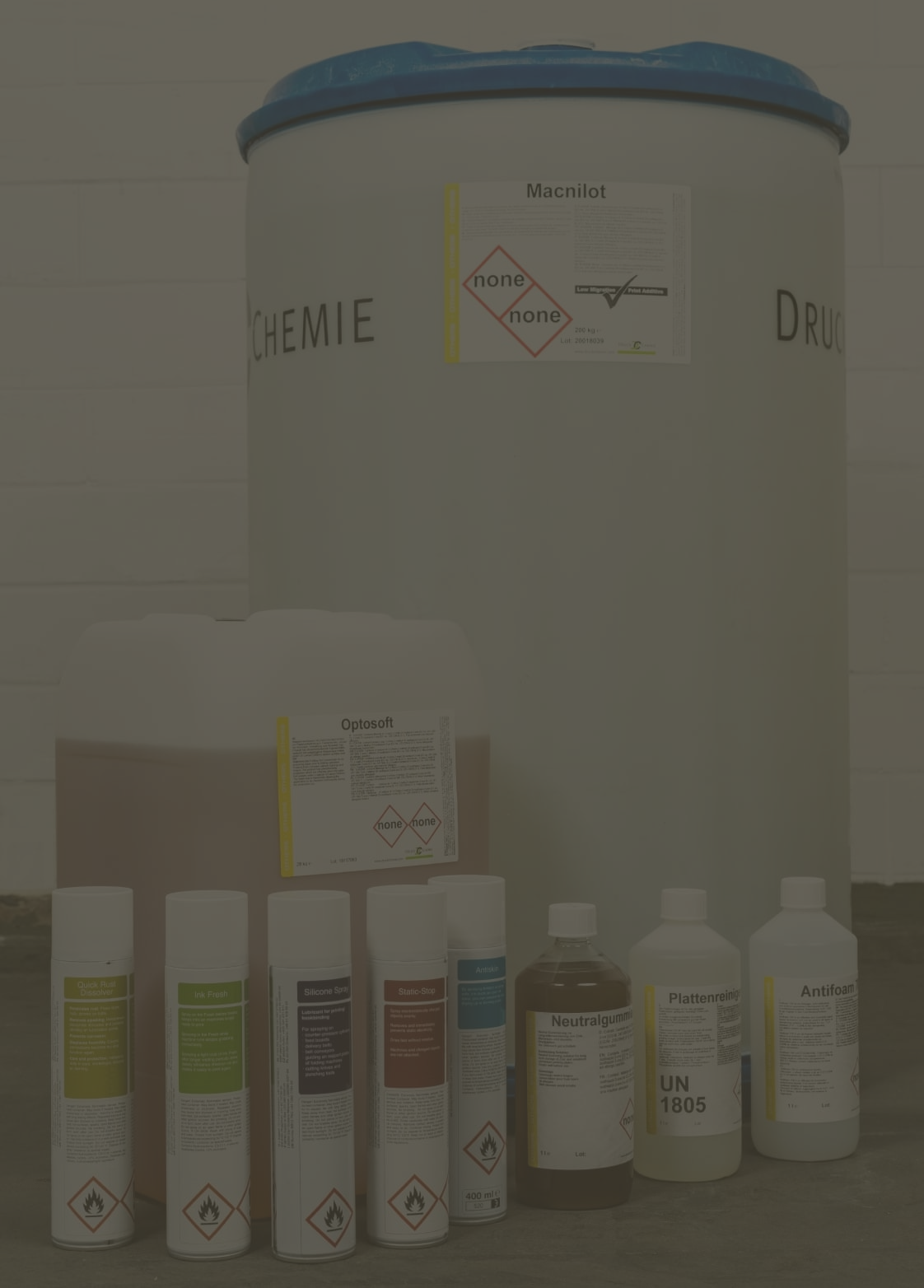

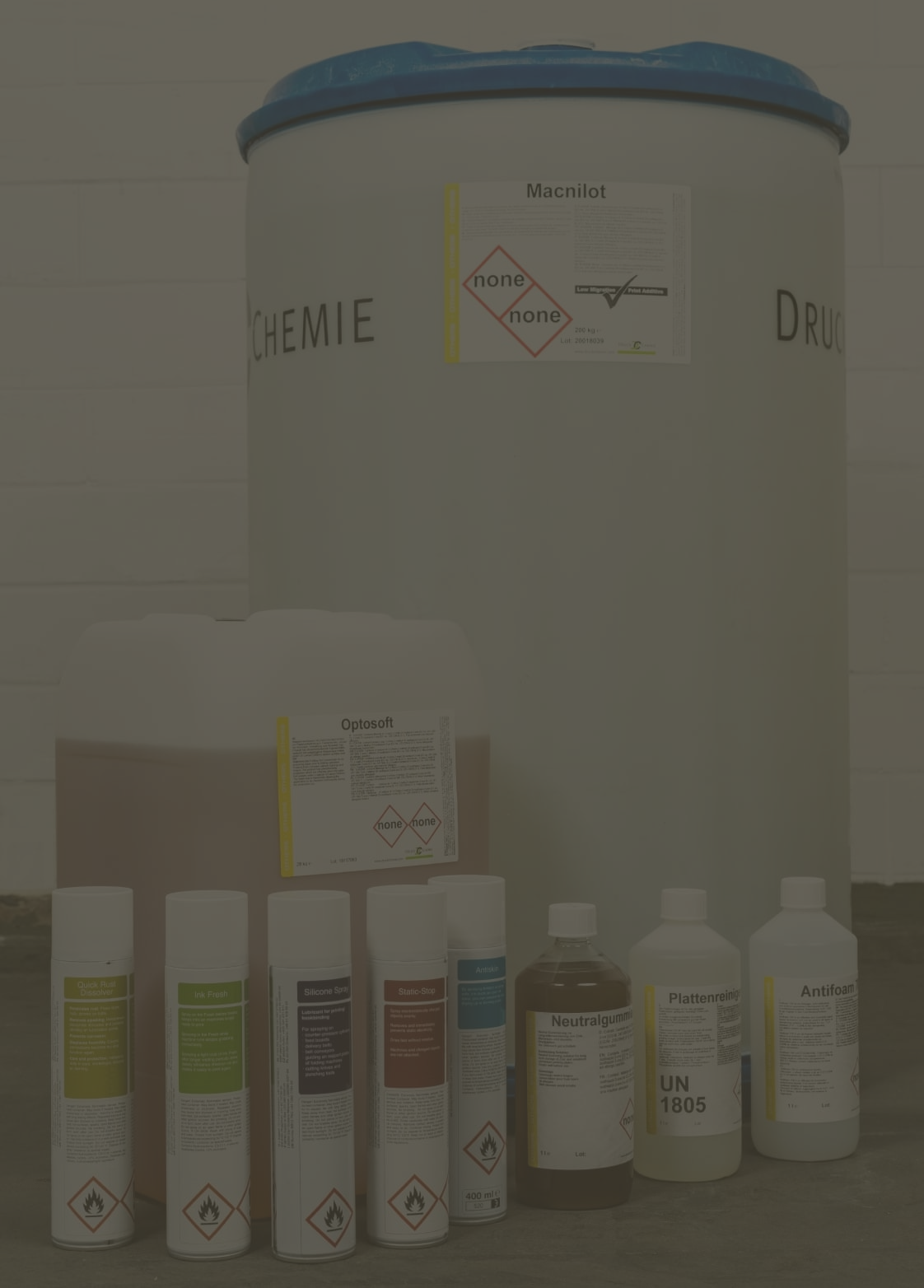

Products

Sheetfed Washing Agents

Through regular laboratory testing, our washing agents are designed to meet the requirements of today’s machinery with their highly developed print applications and configurations.

Heatset Washing Agents

Through regular laboratory testing, our washing agents are designed to meet the requirements of today’s machinery with their highly developed print applications and configurations.

Coldset Washing Agents

Through regular laboratory testing, our washing agents are designed to meet the requirements of today’s machinery with their highly developed print applications and configurations.

Sheetfed Fount Solutions

As a result of advancements in application technology, ever-faster equipment and alcohol-free printing – printing inks, printing plates and printing press types work seamlessly together to produce the best results.

Heatset Fount Solutions

As a result of advancements in application technology, ever-faster equipment and alcohol-free printing – printing inks, printing plates and printing press types work seamlessly together to produce the best results.

Coldset Fount Solutions

As a result of advancements in application technology, ever-faster equipment and alcohol-free printing – printing inks, printing plates and printing press types work seamlessly together to produce the best results.

Silicone Emulsions

Our newly developed Silko® PF product range is an O/W formulation based on PDMS. In combination with scuff protection additives, it offers exceptionally good protection on the paper web.

Glue

DC Druck Chemie is your efficient partner for high-performance adhesives. Our products are specially developed for the graphic industry – and therefore first choice for perfect binding and side glueing of all printed products.

Varnishes

DC Druck Chemie offers a variety of coatings and solutions for special customer requirements. As a certified waste disposal company, we are happy to take back your varnish/coating rinse water.

Printing Aids

DC Druck Chemie offers a wide range of printing aids. Our products not only give your print the perfect look, but they can also increase your productivity by reducing downtimes.

Special Cleaners

As well as many other cleaning applications, Druck Chemie offers innovative special cleaners to remove stubborn dirt in offset printing Different ink solvents, special dampening roller and plate cleaners and water-based cleaning agents are all available, as well as various products for the protection, cleaning and care of printing rollers.

Anti-Set-Off Powders

Our Anti Set-Off powders are characterised by uniform particle sizes and spacing on the substrate. These properties ensure that the sheets are not laid down or folded in the delivery stack – therefore, laminating or varnishing the sheets presents no issue.

Cleaning Cloths

An optimal result with the lowest possible consumption of detergents is the main requirement for a wash cloth for automatic blanket washers. Our washing cloths are consistently designed and quality controlled to accelerate the printing process and minimise delays. DC DruckChemie offers a large selection of different cleaning cloths for everyday printing needs in all possible variants and colours.

Offset Blankets

A stable and high-quality printing process depends on many parameters. One decisive factor is the selection of the proper offset blanket. DC DruckChemie offers a wide variety of offset blankets, which are especially matched to the each area of application.

Flexographic Printing

We now provide our full service offer for flexo printers. We have the infrastructure to develop effective, environmentally friendly solvents and cleaning concepts for every print shop today. Our focus is on practical implementation, so we can maximise benefits for the printer.

Aliphatic hydrocarbons

Aliphatic hydrocarbons are a subgroup of hydrocarbons. They are organic chemical compounds composed of carbon and hydrogen and are non-aromatic.

Aromatic hydrocarbons

Aromatic hydrocarbons are used in the paint, varnish and automotive sectors as components of adhesives, (nitro) varnishes, printing inks, thinners and many other products.

Alcohols

Alcohols are important products and intermediates in the chemical industry. They are the starting materials to produce plasticizers.

Glycol ethers

Glycol ethers are primarily used as solvents, as emulsifying aids in the chemical industry, and as a base for epoxy resins.

Glycol ether acetates

Glycol ether acetates exhibit good solvency and low volatility. Therefore, they are frequently used in the paint, printing, varnish, leather, textile, pharmaceutical, and cosmetic industries.

Ketones

Ketones are oxidation products of secondary alcohols. They are used as solvents and cleaning agents, as well as in the production of plastics.

Acids, Bases & Salts

The industrial uses for acids and bases are many and varied. Acids have a multitude of uses in different industries.

Industrial Cleaners

Suitable for universal use. The cleaners remove grease, oil, soot and other dirt and residues. They clean many surfaces fast and easily, such as metals, glass and many plastics.